ROBOTIC PALLETIZING BY HAMER-FISCHBEIN

A Leader in Packaging Automation

Hamer-Fischbein Robotic Palletizing lines are cost effective solutions for a wide variety of bagging applications. The durable stack box is designed with improved hinging, additional pneumatics and heavier side wall, all of which can stand the test of time in high demand production plants. With single and dual stacking options available, choosing the best application for your packaging area and production output has never been easier.

Semi-Automatic Robotic Palletizer Module (RPM):

The Hamer RPM Robotic Palletizer keeps production numbers at a maximum and is easy to use, providing 80% of palletizing automation at a lower cost than the fully automatic systems.

Semi-Automatic RPM may include:

- Heavy duty in-feed conveyors

- 1 or 3 pallet stack

- MPL 100 or MPL 160 robotic arm

- Complete integration and controls

- Hamer exclusive EasyPicTM operator software pallet configuration

- MaxPicTM pallet configuration

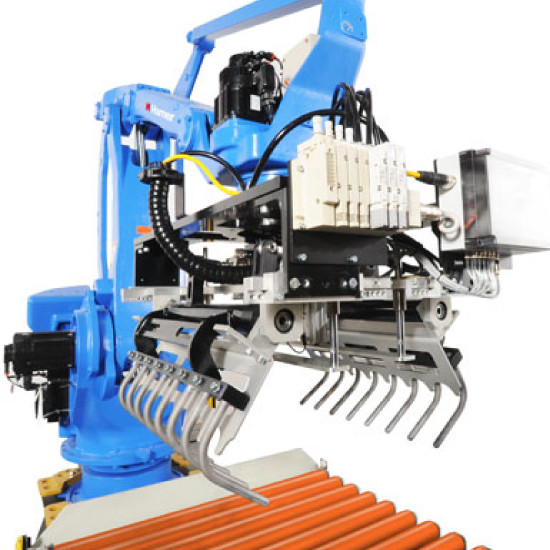

- Industrial design End Of Arm Tooling

- ANSI/RIA safety guard

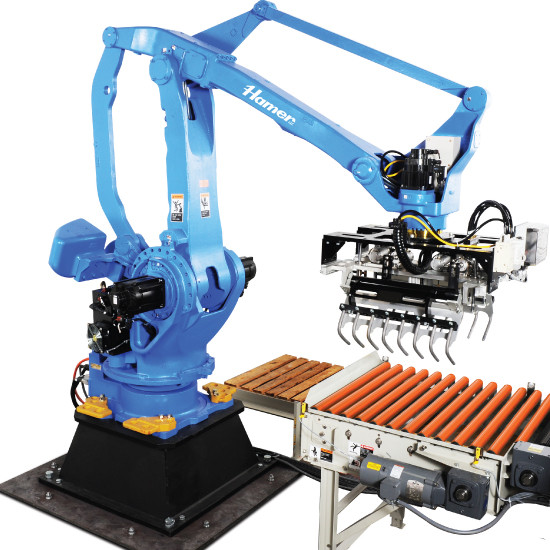

RPM BasicTM, Entry Level Robotic Palletizer:

This model offers semi-automatic and fully automatic palletizing and is ideal for lower production demands offering 16-18 bags per minute, with a max weight of 60 pounds.

RPM Basic, Entry Level Palletizer System may include:

- Semi-automatic configuration with 1 or 2 pallet stack

- Fully automatic configuration with power conveyors

- MPL 160II, 5 axis, 100KG robotic arm

- DX200 Robot Controller

- Robot mounting base plate/riser

- 28” robot riser

- Hamer exclusive EasyPicTM operator software pallet configuration

- MaxPicTM pallet configuration

- Industrial design End Of Arm Tooling

- ANSI/RIA safety protocols

Additional Specs:

- 25 KG End of Arm Tooling

- CDLR Speeds: 60 FPM

- Pass Height: Automated systems use a standard 18” CDLR Top of Roller pass height.

- Electrical: 460/3PH/60Hz

- Air: Clean/Dry Air Required